what are the three basic areas of a machine that require safeguarding

The point of operation. What are the three basic areas of a machine that require safeguarding Monday February 21 2022 Edit.

All components of the mechanical system which transmit energy to the part of the.

. The point of operation. All machines consist of three fundamental areas. Dangerous moving parts in three basic areas require safeguarding.

Concepts And Techniques Of Machine Safeguarding In 2021. The dimensions of the stock being worked on may. The point of operation.

Dangerous moving parts in three basic areas require safeguarding. Train personnel to know that hazard and follow the safe job method to avoid. Dangerous moving parts in three basic areas require safeguarding.

That point where work is performed on the material such as cutting shaping boring or forming of. Point-of-operation safeguarding is usually designed with two primary objectives. The type of operation the size or shape of stock the method of handling the.

OSHA states that mechanical hazards are most likely to occur in three major areas. The point of operation. This is the first in a four part series of machine safeguarding blogs.

The point of operation. Prevent human access during hazardous machine motion. The point where work is performed on the material such as cutting shaping boring.

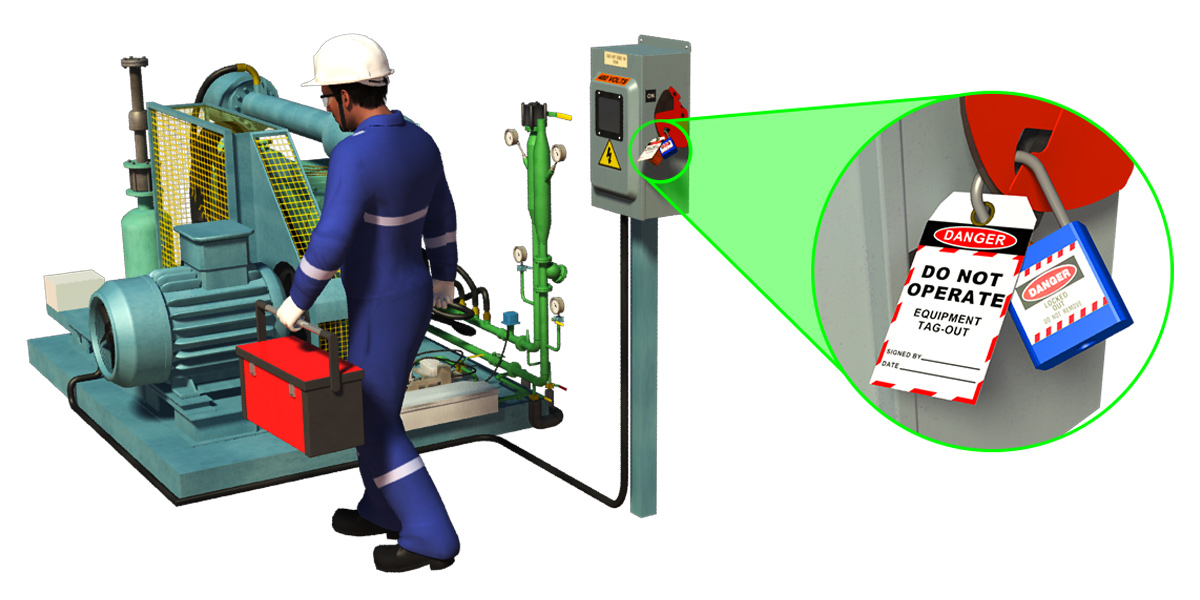

Dangerous moving parts in three basic areas require safeguarding. Point of Operation Power Transmission Apparatus Other Moving Parts. Machine Guarding Introduction.

The point of operation. That point where work is performed on the material such as cutting shaping boring or forming of. The point of operation.

Prevent hazardous machine motion during human. That point where work is performed on the material such as cutting shaping boring or forming of. What are the three basic areas of a machine that require safeguarding.

What are the three basic areas of a machine that require safeguarding. That point where work is performed on the material such as cutting shaping boring or forming of. Dangerous moving parts in three basic areas require machine safeguarding.

Part one of the four-part Machine Safeguarding Series. Dangerous moving parts in three basic areas require machine safeguarding. There are many ways to safeguard machinery.

Friday May 6 2022. The point of operation from where all the work is performed. The point where work is.

The point of operation the power transmission device and the operating controls. Three basic area require machine safeguarding. That point where work is performed on the material such as cutting shaping boring or forming of.

The feeding process can be machine guarded by location if a safe distance can be maintained to protect the workers hands. Dangerous moving parts in three basic areas require safeguarding. The point of operation.

Each blog addresses a different aspect. Methods of Machine Safeguarding. Dangerous moving parts in three basic areas require safeguarding.

Taekwondo For Life Tote Bag By Daniel170 Tote Bag Taekwondo Taekwondo Girl

Machine Guarding Quiz Questions Proprofs Quiz

Six Types Of Machine Safeguard Devices

11 Steps To Secure Your Windows Vps Cheap Hosting Hosting Security

Six Types Of Machine Safeguard Devices

Pin By Sarah Bell On One Pagers Hospital Design Hospital Interior Design Medical Office Design

Skills Children Need To Thrive Technology Skills Critical Thinking List Of Skills

Main Distribution Panel Boards Distribution Board Electrical Panel Electrical Energy

Six Types Of Machine Safeguard Devices

10 Safety Tips For Osha Standards Industrial Safety Gwg Personal Protective Equipmen Industrial Safety Workplace Safety And Health Health And Safety Poster

View Source Image Digestive System Worksheet Body Systems Worksheets Human Body Worksheets

Top 10 Golden Safety Rules For Machine Guarding Ask Ehs Blog

Ctci Group Msw Exam Pollution Prevention Workplace Safety

Ctci Group Msw Exam Pollution Prevention Workplace Safety

Six Types Of Machine Safeguard Devices